[ad_1]

Scientists at a Scottish college imagine they’ve found a method to turn wastewater from the whisky trade into sustainable fuel for the future.

A group from Heriot-Watt University have developed supplies that may use wastewater from distilleries to provide inexperienced hydrogen which, in contrast to fossil fuels, doesn’t produce carbon when it’s burned.

Green hydrogen is generally created utilizing contemporary water in a course of thought to eat round 20.5 billion litres of contemporary water yearly.

The Heriot-Watt group hope the materials they’ve developed will see a few of the estimated one billion litres of wastewater produced by the distilling trade annually used to create inexperienced hydrogen as an alternative.

We want to scale back our use of contemporary water and different pure sources

Dr Sudhagar Pitchaimuthu

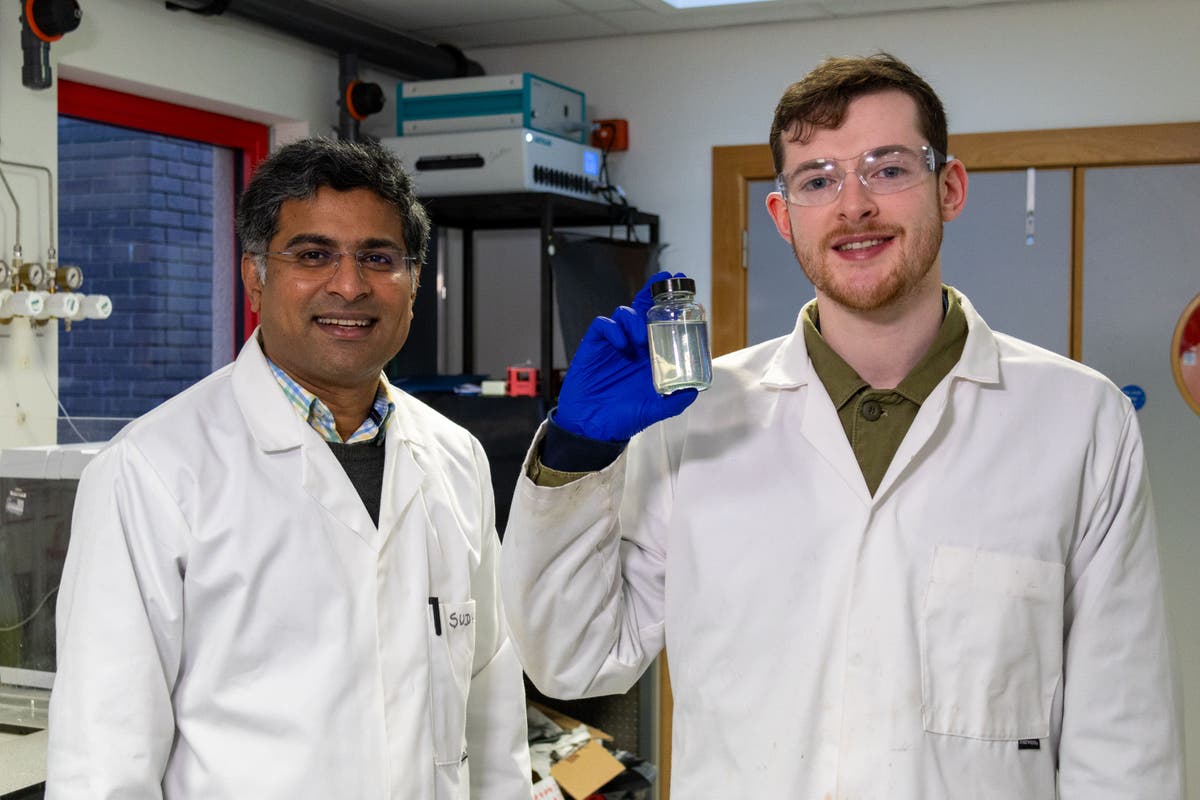

Dr Sudhagar Pitchaimuthu, a supplies scientist at the college’s School of Engineering and Physical Sciences, defined: “It takes nine kilogrammes of water to produce every one kilogramme of green hydrogen. Meanwhile, every one litre of malt whisky production creates about 10 litres of residue.

“To help protect the planet, we need to reduce our use of fresh water and other natural resources. So our research focused on how to use this distillery wastewater for green hydrogen production with a simple process that removes waste materials present in the water.”

Dr Pitchaimuthu and his group have developed a nanoscale materials – a particle one in 10,000th the diameter of a human hair – to permit distillery wastewater to switch contemporary water in the inexperienced hydrogen manufacturing course of.

The nanoparticle, referred to as a nickel selenide, treats the wastewater and produces comparable or barely larger portions of inexperienced hydrogen from the water throughout analysis in comparison with contemporary water.

The analysis is revealed in the Royal Society of Chemistry journal, Sustainable Energy & Fuels, in a paper authored by Dr Pitchaimuthu’s PhD scholar, Michael Walsh, who performed a key function in conducting the analysis.

Using trade wastewater means we are able to scale back the intensive freshwater footprint related to inexperienced hydrogen manufacturing

Dr Sudhagar Pitchaimuthu

“About one billion litres of wastewater a year is produced from the distilling industry, so the potential of this process is huge,” Dr Pitchaimuthu continued.

“Using industry wastewater means we can reduce the extensive fresh water footprint associated with green hydrogen production. Our research also shows how we can use the world’s resources more sustainably to produce clean energy.”

The subsequent steps for the Heriot-Watt analysis group embody creating their very own electrolyser prototype and scaling up manufacturing of their nickel selenide nanoparticles.

They may also analyse distillery wastewater to find whether or not different supplies of worth might be salvaged from it, alongside hydrogen and oxygen.

The analysis was funded by Heriot-Watt’s School of Engineering and Physical Sciences and accomplished in collaboration with the University of Bath’s Department of Chemical Engineering and The Scotch Whisky Research Institute.

[ad_2]

Source hyperlink