[ad_1]

You simply knew this was coming. No doubt, you have heard about the staffing shortages in factories. And guess what? The answer appears to be robots.

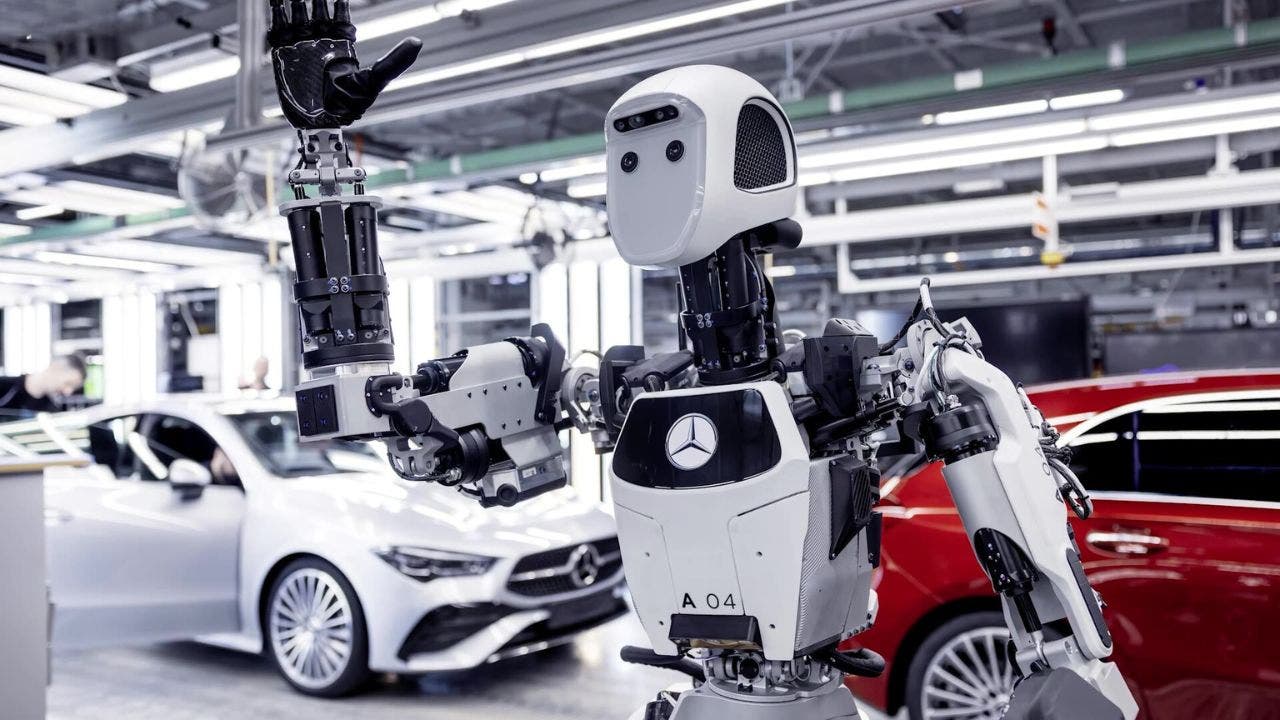

At Mercedes-Benz Manufacturing in Hungary, they’ve swapped out a few of their human staff for humanoid robots proper there on the manufacturing unit ground. These futuristic robots are produced by Apptronik, a Texas-based firm.

Mercedes-Benz and Apptronik have teamed as much as discover how these robots can lend a serving to hand to their human counterparts. The purpose? To deal with staffing challenges throughout the manufacturing course of.

Apollo, the humanoid robot at a Mercedes-Benz manufacturing unit. (Apptronik)

The humanoid robot workmate

The humanoid robots are known as Apollo. Standing at a top of 5 toes 8 inches and weighing in at 160 kilos, Apollo mirrors the proportions of a human employee. Its mission? To collaborate seamlessly with its human counterparts whereas tackling bodily demanding duties.

WHAT IS ARTIFICIAL INTELLIGENCE (AI)?

Apollo the robot works at a Mercedes-Benz manufacturing unit. (Apptronik)

MORE: AI ROBOT THAT CAN TRIM, EDGE AND BLOW YOUR LAWN FOR YOU

The robot’s power and agility

Apollo’s highly effective arms can raise as much as 55 kilos at a time, making it a precious asset in an assembly line atmosphere. Its swappable battery ensures a runtime of roughly 4 hours per pack, sufficient to maintain it going by means of a productive shift.

Apollo the humanoid robot does work in a Mercedes-Benz manufacturing unit. (Apptronik)

MORE: THIS ROBOT INVENTION CAN DO BACKFLIPS BETTER THAN A GYMNAST

Is the robot secure?

Apollo’s distinctive drive management structure permits it to function safely alongside people. Think of it as a collaborative robot, not an industrial behemoth. No have to barricade off sections of the manufacturing unit; Apollo integrates seamlessly into current areas.

Apollo the robot works on a automobile at a Mercedes-Benz manufacturing unit. (Apptronik)

MORE: THIS HUMANOID ROBOT IS NOW CAPABLE OF FULL CONVERSATIONS

The robot’s purposes in manufacturing amenities

Apollo’s first process? Logistics. It shuttles components to the production line, making certain staff have what they should assemble autos. So, for instance, Apollo delivers assembly kits whereas concurrently inspecting parts. Later in the course of, Apollo takes on one other vital function: delivering totes of kitted components. These neatly organized containers include all the things mandatory for particular assembly steps.

Apollo the robot at a Mercedes-Benz manufacturing unit. (Apptronik)

How the robot is bridging the labor hole

Mercedes-Benz faces a typical problem: discovering dependable staff for bodily demanding, repetitive, boring duties. That’s the place Apollo is available in and bridges the hole. The firm says these robots enable them to automate duties and unencumber expert workers to give attention to higher-value work. They say it’s a win-win for productiveness and job satisfaction. However, it’s unclear what number of robots will probably be used at their factories.

GET FOX BUSINESS ON THE GO BY CLICKING HERE

An in depth-up of Apollo the humanoid robot on a Mercedes-Benz manufacturing unit ground. (Apptronik)

Robots on the assembly line

But Mercedes-Benz isn’t the solely participant on this recreation. Earlier this 12 months, BMW made waves by partnering with California-based Figure to place its robots to the take a look at. The star of the present? Figure’s 01 robot, at present laborious at work in BMW’s U.S. factories positioned in Spartanburg, South Carolina.

Kurt’s key takeaways

Both Mercedes-Benz and BMW are nonetheless fine-tuning their method, determining how finest to leverage these robots. The purpose? To automate these difficult, unsafe or downright tedious duties which have historically fallen on human shoulders. From delivering and inspecting components to working alongside expert staff, these robots are poised to revolutionize the assembly line.

CLICK HERE TO GET THE FOX NEWS APP

Is this a step in the proper route, or is that this simply one other solution to exchange human jobs with automation, probably resulting in job displacement? Let us know by writing us at Cyberguy.com/Contact

For extra of my tech suggestions & safety alerts, subscribe to my free CyberGuy Report Newsletter by heading to Cyberguy.com/Newsletter

Ask Kurt a query or tell us what tales you need us to cowl.

Answers to the most-asked CyberGuy questions:

Copyright 2024 CyberGuy.com. All rights reserved.

[ad_2]

Source hyperlink